History of Yarn Count

The concept of yarn count dates back to centuries ago when the need for precise measurement of yarn thickness and weight became essential in textile production. One of the earliest yarn counting systems was introduced in Europe during the 18th century. Although it is unclear whether a specific individual invented this system, early advancements in this field are attributed to British textile workshops. Over time, these systems evolved and were standardized by industrial and scientific associations.

Among the most influential early standards was the English Yarn Count System, which took shape during the early stages of the Industrial Revolution. During this period, the development of textile technologies and machinery heightened the need for a more precise method to describe yarns.

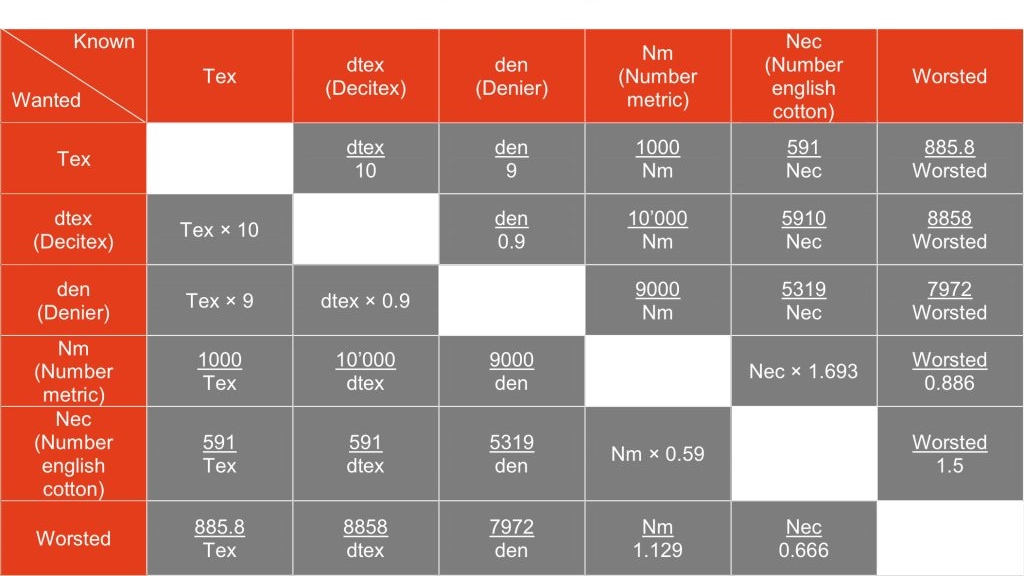

Definition of Yarn Count

Yarn count is a measure that describes the thickness or weight of yarn relative to its length. There are two primary methods for determining yarn count:

1. Direct System: Measures the fixed weight of yarn per a specific length (expressed in grams per meter).

2. Indirect System: Measures the fixed length of yarn per a specific weight (expressed in meters per gram).

Types of Yarn Count

1. Metric System (Metric Number - Nm)

In this system, the number of meters of yarn per gram is calculated. A higher value indicates a finer yarn.

Nm =(L/W)*(1/K) K:1

2. Denier System (Den)

The denier system is used for filament yarns, such as synthetic fibers, and measures the weight of yarn per 9,000 meters. A lower denier indicates a finer yarn.

Den =(W/L)*K K:9000

3. Tex System (Tex)

The tex system is similar to denier but measures the weight of yarn per 1,000 meters.

Tex =(W/L)*K K:1000

4. English Cotton Count System (Ne)

In this system, the number of 840-yard hanks of yarn that weigh one pound is calculated. A higher count indicates finer yarn.

Ne =(L/W)*(1/K) K:840

5. Worsted Count System (Nw)

This system is used for wool yarns and indicates the number of 560-yard hanks in one pound of yarn.

Nw =(L/W)*(1/K) K:1600

Applications of Yarn Count

1. Fabric Design and Production: Selecting the appropriate yarn for producing fabrics with specific characteristics.

2. Quality Control: Ensuring yarn uniformity and adherence to standards.

3. Textile Machinery: Adjusting machines according to yarn specifications.

4. International Trade: Facilitating comparison and procurement of yarn in global markets.

Yarn count is one of the most crucial measurement tools in the textile industry, with various systems applied depending on the intended use. With technological advancements, these systems have been continuously optimized to meet the evolving needs of the industry.

Comments :